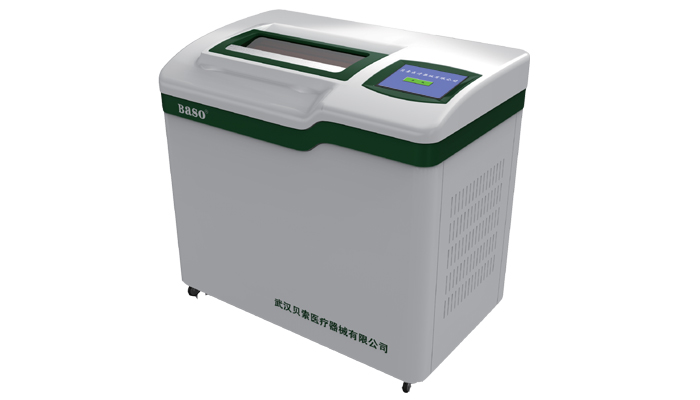

Plasma Thawing System

(Intelligent Temperature Control)

Features:

1. Convenient ways to thaw

Five thawing modes available:

A. Normal mode; B. floating thaw control endpoint; C. procedure cooling mode;

D. Manual mode; E. Emergency insert mode;

2. Quality control system

A. Quality control in normal mode

By analyzing the simulating plasma bag's feedback data, Baso's Plasma Thawing System adjusts the thawing

process accordingly to ensure quality of the thawed plasma (Core temperature is 33°C);

B. The quality management of the water monitoring system

By examining the temperature difference (△T) between the upper and lower water tank temperature probes,

it can monitor accuracy of the temperature probes to meet the quality control requirements.

3. QC data traceability

In the thawed state, the instrument can dynamically test and analyze the core temperature of analog plasma

bags, and the temperature of the upper and lower water tanks. The results are automatically saved to

provide quality management and traceability data.

4. Intelligent operating system

A touch-screen interface provides real-time display of temperture/time curve. Moreover, a user-friendly

troubleshooting system facilitates repair by providing specific error messages that pinpoint the location

and cause of problem.

Technical Parameters:

|

Model |

BSJD-I-22/BSJD-T-01 |

BSJD-Y-32/12 |

|

Thawing Mode |

Five modes available |

On the same device, dry or wet thawing can be operated for only replace the plasma frame, the first dry and wet dual-use model in China. |

|

Max.Plasma Capacity |

200ml 28bags/12bags |

200ml 32bags/12bags |

|

QC Data Traceability |

In the thawed state, the instrument can dynamically test and analyze the core temperature of analog plasma bags, and the temperature of the upper and lower water tanks. The results are automatically saved in order ot provide quality management and traceability data. |

|

|

Water Temperature Monitoring System |

The temperature difference (△T) between the upper and lower water tank temperature probes is analyzed to determine whether the accuracy of the temperature probes meet the quality control requirements. |

|

|

QC System |

By analyzing the simulating plasma bag’s feedback data, Baso's Plasma Thawing System adjusts the thawing process accordingly to ensure quality of the thawed plasma. |

|

|

WIFI |

Support WIFI function; Data can be saved and transported to the PC though WIFI and the real-time data display in the LCD. |

|

|

Intelligent Operation System |

Microcomputer touch screen provides a real-time display of Temp. / Time curve. A user-friendly troubleshooting system facilitates repair by providing specific error messages that pinpoint the location and cause of problem. |

|

|

Data Records and Storage |

Up to 2000 sets data can be processed, recorded and stored. |

|

|

Scanning Function |

Scanner available; barcode scanning and entry data |

|

|

Pump Capacity |

60L/min or 30L/min; Automatic filling and drainage, preheating, heating, and cycling. |

Integrated water tank with automatic filling/draining, preheating, heating and cyclic cleaning. |

|

Rated Power |

4000W |

4000W |

|

Weight |

140KG/45KG |

140KG |

|

Dimensions (L*W*H) |

1000*640*940(mm)/ 730*450*370(mm) |

1000*640*940(mm) |

|

Temperature range and precision |

Room temperature ~41°C / ± 0.1°C |

|

|

Vibration frequency |

30r/min |

|

|

Thawing time |

Completion of a full load of bags within 30 min. |

|

|

Time function |

1~99 min |

|

|

Power Supply |

220v ± 10% / 50Hz |

|